| Availability: | |

|---|---|

| Quantity: | |

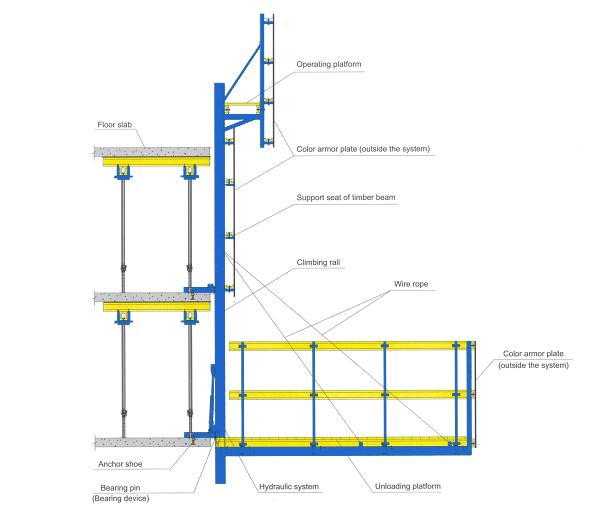

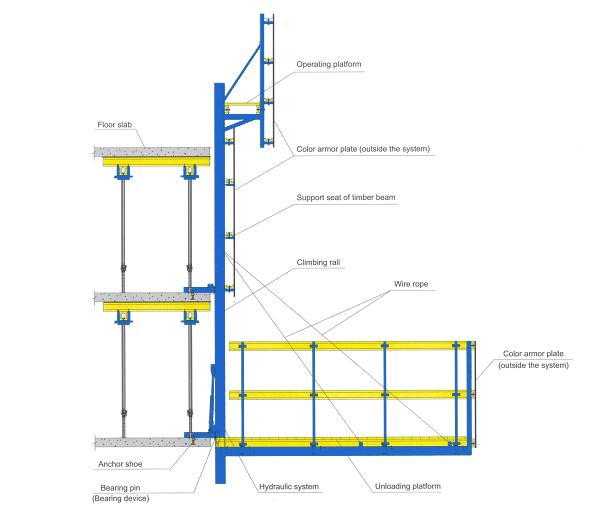

Protection Screen and Unloading Platform Introduction

Protection screen is a safety system in the construction of high-rise buildings. The system consists of rails and hydraulic lifting system and is able to climb by itself without crane. Protection screen has the entire pouring area enclosed, covering up three floors at the same time, which can more effectively avoid falling from height (FFH) and ensure the safety of the construction site.

The system can be equipped with unloading platforms. After pouring the slab, the formwork and scaffolding can be transported to the unloading platform, and then they will be lifted by tower crane to the upper level for the next step working, so that it greatly saves manpower and material resources and improves the construction speed.

The protection screen is an advanced, state-of-the-art system which suits the demand for safety and civilization on site, and it indeed has been widely used in high-rise tower construction.

Furthermore, the exterior armor plate of the protection screen is a good advertising board for publicity of the contractor.

Structure diagram

Introduction to auto-climbing protection screen

1. Anchor system

The anchor and the anchor shoe are the main load bearing parts of the protection screen. The anchor shoe is fixed on the floor by tensile bolt. The anchor system consists of the following components:

2.Standard components

Anchor shoe |

Hydraulic system |

Climbing rail |

①Console bracket ②Diagonal brace ③Standard |

Bearing device |

Unloading platform ①Main beam ②Cross beam No.1 ③Cross beam No.2 ④Standard |

3.Hydraulic and load bearing system

The power of the protection screen system comes from the hydraulic system, which lifts the climbing rails up gradually, thus enabling the entire protection screen system to climb up 300 mm every time. The picture below shows the powering part of the protection screen. Insert the load bearing pin when the rail climbs to the desired position.

The load-bearing device is installed in the middle of each rail as a movable load-bearing part.

Anchor system installation

①Assemble the climbing cone and anchor plate, then pre-embedding them into the floor.

②Fix the anchor shoe on the floor by tensile bolt.

③The anchor shoe after fixing.

Protection Screen and Unloading Platform Introduction

Protection screen is a safety system in the construction of high-rise buildings. The system consists of rails and hydraulic lifting system and is able to climb by itself without crane. Protection screen has the entire pouring area enclosed, covering up three floors at the same time, which can more effectively avoid falling from height (FFH) and ensure the safety of the construction site.

The system can be equipped with unloading platforms. After pouring the slab, the formwork and scaffolding can be transported to the unloading platform, and then they will be lifted by tower crane to the upper level for the next step working, so that it greatly saves manpower and material resources and improves the construction speed.

The protection screen is an advanced, state-of-the-art system which suits the demand for safety and civilization on site, and it indeed has been widely used in high-rise tower construction.

Furthermore, the exterior armor plate of the protection screen is a good advertising board for publicity of the contractor.

Structure diagram

Introduction to auto-climbing protection screen

1. Anchor system

The anchor and the anchor shoe are the main load bearing parts of the protection screen. The anchor shoe is fixed on the floor by tensile bolt. The anchor system consists of the following components:

2.Standard components

Anchor shoe |

Hydraulic system |

Climbing rail |

①Console bracket ②Diagonal brace ③Standard |

Bearing device |

Unloading platform ①Main beam ②Cross beam No.1 ③Cross beam No.2 ④Standard |

3.Hydraulic and load bearing system

The power of the protection screen system comes from the hydraulic system, which lifts the climbing rails up gradually, thus enabling the entire protection screen system to climb up 300 mm every time. The picture below shows the powering part of the protection screen. Insert the load bearing pin when the rail climbs to the desired position.

The load-bearing device is installed in the middle of each rail as a movable load-bearing part.

Anchor system installation

①Assemble the climbing cone and anchor plate, then pre-embedding them into the floor.

②Fix the anchor shoe on the floor by tensile bolt.

③The anchor shoe after fixing.

Building High and Safe with Lianggong Hydraulic Auto-Climbing Formwork SystemThe construction of high-rise buildings is a complex and challenging process that requires advanced technology and expertise. Among the many critical components of high-rise construction, the formwork system is one of the m

Lianggong Formwork Outstands Itself in the Construction of Safe and Innovative Bridges: Examples of Lianggong Formwork Systems in Bridge ProjectsLianggong formwork systems have been used in various bridge construction projects around the world. The systems provide a cost-effective, efficient, and sa

Tunnel Formwork Projects Using Lianggong’s Formwork SystemsLianggong is a leading manufacturer in the production and sales of formwork and scaffolding based in China, providing formwork solutions for infrastructure projects around the world, including many tunnel projects. Their tunnel formwork syst